GEM's cobalt-nickel business mainly extracts cobalt-nickel raw materials from waste cobalt-nickel resources to produce high-end powder materials such as cobalt carbonate, cobalt oxalate, nickel carbonate, nickel oxalate and cobalt powder etc. Since 2016, when GEM acquired Shu Metal, GEM's recycled cobalt resources finally entered the supply chain of international head alloy manufacturers such as Sandvik and Kennametal, marking that the cobalt materials re-constructed by GEM's recycled cobalt resources were recognized by international head enterprises. Shu Metal's cobalt powder business and GEM’s advantages in market and technology form a benign complementary relationship, bringing into playing synergistic effects thus enhancing GEM's competitive advantages, building GEM's world-renowned cobalt powder brand, consolidating its leading position and occupying more than 40% of the global market.

GEM continues to consolidate and expand its long-term strategic partnership with foreign mineral giants, and has signed long term orders with international mining giants such as Canco and Liqin to lock in strategic raw material supply, further enhancing GEM's ability to guarantee the supply of cobalt powder and its core competitiveness.

Second Prize of National Science and Technology Progress

GEM continues to consolidate and expand its long-term strategic partnership with foreign mineral giants, and has signed long term orders with international mining giants such as Canco and Liqin to lock in strategic raw material supply, further enhancing GEM's ability to guarantee the supply of cobalt powder and its core competitiveness.

In 2002, GEM started the experimental development of cobalt powder production in Taohuayuan, Baoan District, Shenzhen; in 2004, GEM built the production base of the first phase of ultra-fine cobalt and nickel powder and cobalt carbonate, cobalt oxalate, nickel carbonate and nickel oxalate in Jingmen Park; in 2006, GEM built the second phase of ultra-fine cobalt and nickel powder production line in Jingmen Park; in 2009, GEM completed nickel sulfate production line and started to produce nickel-iron alloy to supply Rio Tinto and other large international companies. In 2016, the company acquired Shu Metal and became the world's largest cobalt powder manufacturer; in 2017, the company stopped its nickel powder business. Between 2010 and 2021, the company's cobalt carbonate and cobalt powder production capacity continued to expand and became the head of the industry.

The cobalt-nickel business of GEM is based in Jingmen, Hubei Province, and laid out in South Africa, forming a benign complementary in market and technology and playing the synergy effect, so as to enhance GEM's competitive advantages and build GEM's world-renowned brand of cobalt powder. At present, in Jingmen, Hubei, GEM is building a cobalt powder production line with an annual capacity of 3,000t/n and a cobalt carbonate precursor production line with an annual capacity of 12,000t/n; South Africa Shu Metal Company is building a superfine cobalt powder production line with an annual capacity of 1,500t/n.

Cobalt-Nickel Industry Layout of GEM

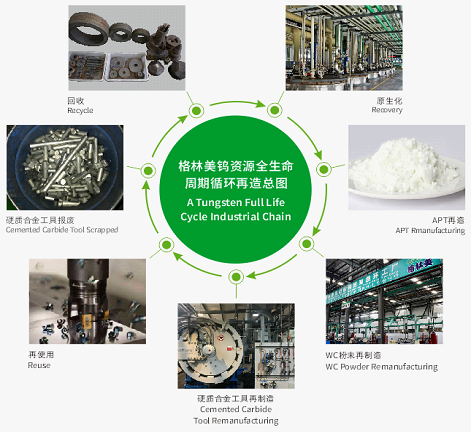

GEM tungsten resource recycling business was founded in 2011, and the main body of its implementation is Hubei Green Tungsten Resource Recycling Co. The company is mainly engaged in the recycling and resource utilization of waste tungsten resources, the key technology research and development and industrial production of recycled ammonium paratungstate (APT), tungsten oxide, tungsten powder, tungsten carbide and other powder products, creating a tungsten resources whole life cycle of industry chain as "waste tungsten resources--APT--tungsten powder--high performance tungsten powder--high performance tungsten carbide--tungsten carbide" , obtaining APT, tungsten oxide, tungsten powder, tungsten carbide and other recycled re-manufactured tungsten powder products. With the ESG concept, the company promotes the deep integration of tungsten resource supply chain, industry chain, innovation chain and value chain, realizes the efficient green recycling of waste tungsten resources, and builds a new height of sustainable utilization of tungsten resources in the double carbon era.

Whole Life Cycle of Recycling of Tungsten Resources

GEM has established a perfect technology research and development system, created a provincial-level enterprise and university joint innovation center and provincial-level enterprise technology center dual provincial-level science and technology innovation strategy platform, and created a complete key technology route of waste tungsten resource recycling. The company's products are mainly supplied to renowned enterprises as Chinatungsten High-Tech, Zhu Drilling, Zhu Hard Group, Foxconn, Xiamen Tungsten, OUKEY, etc. The amount of tungsten metal recovered in 2021 is nearly 4,000 tons, which is more than 5% of China's original tungsten mining volume. 20 years of the company's cumulative tungsten metal recovery exceeds 30,000 tons, which is equivalent to mining a large tungsten mine, and the cumulative reduction of carbon emissions realized by cobalt-nickel-tungsten metal recovery and re-manufacturing reaches 1.47 million tons, which is equivalent to planting 147 million trees and realize afforestation of 980,000 acres.

Advantages of GEM’s Tungsten Resources Recycling Industry

In 2021, Hubei Green Tungsten Resources Recycling Co., Ltd. completed the signing of the hybrid reform, marking that the business segment of GEM, which is mainly engaged in tungsten resources recycling, will independently plan to enter the capital market, set sail with low-carbon, continue to promote the development of tungsten resources and become a world leader in tungsten resources recycling. In the future, the company will expand its overseas recycling channels, focus on high performance tungsten carbide products such as ultra-fine and ultra-coarse tungsten carbide, expand the production capacity of ultra-fine and ultra-coarse tungsten carbide to 2,500 tons, and plan to recycle tailing slag up to 10,000 tons. GEM will cooperate w

BottomGraphic · MainBusiness · CentralScroll ·

GEM Introduction Guangdong ICP No. 11096806-1©2008-2021 GEM Co., Ltd. All rights reserved

Address:Sopo Del Tower A Lantai 22 Unit A, Jalan Mega Kuningan Barat 3 Lot 10.1-6 Kawasan Mega Kuningan, Jakarta Selatan 12950

Telephone:+62-2150806594

Scan QC Code

BottomGraphic · MainBusiness · CentralScroll · GEM Introduction Guangdong ICP No. 11096806-1©2008-2021 GEM Co., Ltd. All rights reserved